BHP NPI INLAND HV SCADA UPGRADE

CLIENT: BHP LOCATION: Pilbara, WA. SCOPE: HV Substation SCADA and communications design, configuration, testing & commissioning at Yandi and Junction. TECHNICAL SITUATION Yandi and Junction substations…

APD provides the full range of engineering design, configuration, testing & commissioning services for Protection, Automation and Control systems (PACs) in HV transmission & distribution substations and process plants.

The team openly adopts new cutting-edge technology that has been proven in the international PACs space to improve the design, applications, performance and asset management of system protection, substation control and automation, remote control systems and metering systems.

Offering HV Substation Protection and Automation systems design services, from concept studies to detailed design.

Core expertise of the team is in configuration of HV substation protection relays, gateways, network switches and (HMIs).

Test the configured hardware & software against the protection & control philosophy / functional specification, prior to shipping to site.

Functional testing, dry and wet commissioning of the HV plant to meet the protection & control philosophy / functional specification.

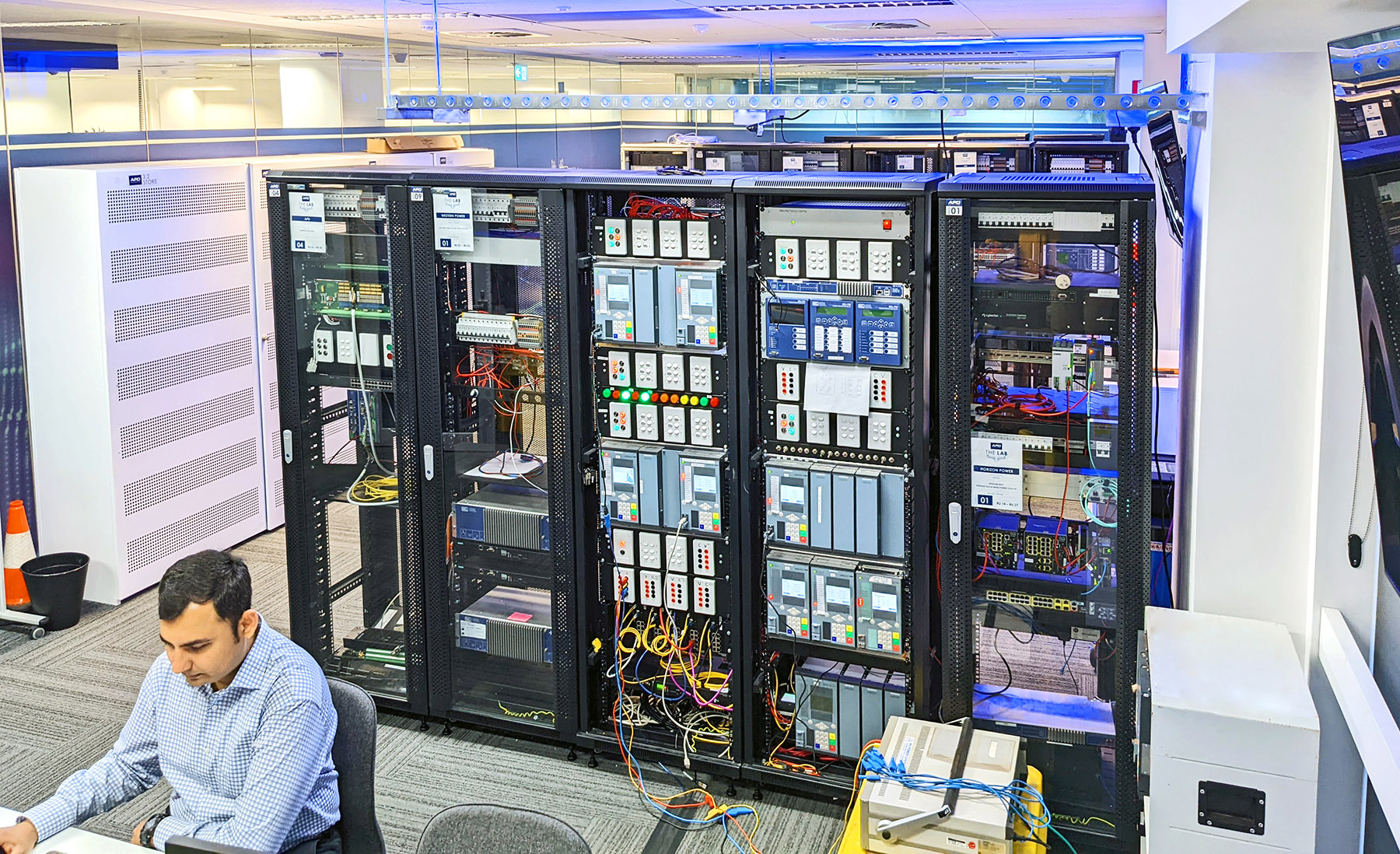

Our PACs team is equipped with a state-of-the-art ‘Lab’ at our Perth head office. The unprecedented demand on our testing environment means this 60 square metre secure area serves to further cater for various new HV Substation Protection & Automation projects.

The enhanced functionality, new testing & staging panels, networking equipment, media converters, workstations & monitors, offer our team additional flexibility to perform Protection & Automation testing, configuration, internal testing and client-witnessed FAT testing. It also facilitates technical training and serves as a hub for client meetings and presentations.

This most reliable asset allows APD to simplify the problem elimination process, ultimately saving our Clients’ valuable time and resources. The confidence a fully-tested system brings to power utility and mining operations is critical in the successful integration of new loads and new renewable generation assets such as wind farms, solar farms and battery energy storage systems (BESS).

We work with industry-approved technologies & protocols to meet the needs of our clients’ operational requirements. Many of these technologies have become industry standards due to their reliability, support & wide application. We make it our business to be at the forefront with technologies, which are the essential tools of our trade.

APD Engineering value and appreciate our clients’ business goals – working closely with them to understand their business and help realise their opportunities and overcome the challenges. However, we value our clients’ trust in our capability above all, and we always strive to meet this high expectation.

Additionally, APD’s industry and vendor relationships keep us at the forefront of new product developments, design standards and principles to build a robust, secure, and maintainable systems.

CLIENT: BHP LOCATION: Pilbara, WA. SCOPE: HV Substation SCADA and communications design, configuration, testing & commissioning at Yandi and Junction. TECHNICAL SITUATION Yandi and Junction substations…

CLIENT: Woodside LOCATION: Karratha, Pilbara, WA. SCOPE: APD was engaged in the definition phase of the Pluto Solar Import control integration into the Pluto Power…

CLIENT: Western Power LOCATION: East Rockingham, WA. SCOPE: To provide automation configuration, testing & commissioning works at the Office Rd connection substation & remote ends…

CLIENT: Western Power / AEMO LOCATION: Collie, WA & Muja, WA. SCOPE: To provide the substation automation design, configuration, testing, construction & commissioning works at…

APD Engineering were engaged by Alinta Energy to provide Owner’s Engineering services for the Chichester Solar Farm.

APD Engineering was engaged by TransGrid, to provide the automation configuration, testing & commissioning support works, for the greenfield Berrybank wind farm connection substation and…

The Roy Hill Ultrafine Iron Recovery Facility required the repurposing of a 33kV switchboard, originally from the thier Port, integrated into their Mine’s PMS.

APD Engineering was engaged to perform the process control system commissioning of the new plant, enabling the automatic operation of the new plant equipment and…

APD Engineering was hired to perform design & implementation of the Power Load Management Control System & Network Upgrade.

APD Engineering delivered the project’s fuel facility control system to the client’s specifications. Also provided support to the power station operators post-delivery.

APD was hired to perform the design and engineering of Secondary, Automation, Communications and Protection in relation to the replacement of the relay substation and…

APD Engineering delivered & integrated the control systems for the new lubrication racks for the HME service bays, LV Workshop & the Bulk Re-Fueling Facility